The Uttendorf Vitzthum Brewery is a brewery rich in tradition, which has its origins in the picturesque village of Hepfau-Uttendorf. Beer has been brewed here with great passion for many generations, and the result is first-class beers of the highest quality. The family business places great emphasis on traditional brewing craftsmanship and uses only selected raw materials to offer a unique taste experience.

A visit to the Uttendorf Vitzthum brewery and brewery inn is definitely worthwhile. Here you can get an insight into the traditional art of brewing during a guided tour of the brewery and then get to know the different types of beer during a tasting. The brewery inn also invites you to linger in comfort and offers regional specialties that harmonize perfectly with the beers. The Vitzthum family is proud of its long history and heritage, and it does everything it can to carry on the brewing tradition with innovation and passion. With its outstanding beers, it delights not only locals but also beer lovers from all over the world. Cheers to the Uttendorf Vitzthum Brewery and its delicious beers!

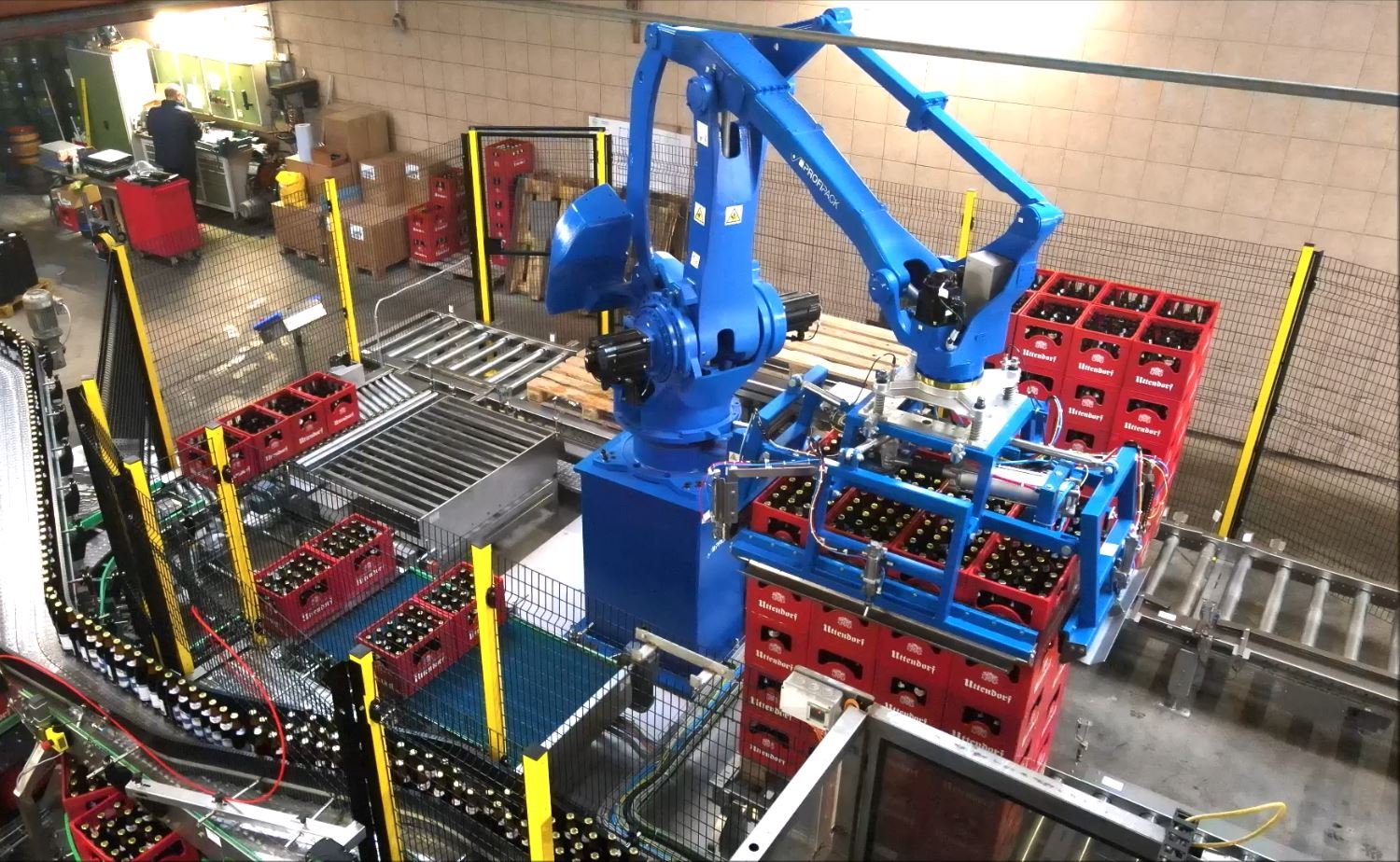

In 2022, the family council decided to renew the palletizing system. The old palletizing system was replaced by a loading and depalletizing robot from Profipack. The challenge was mainly the space conditions. Profipack succeeded in designing a palletizing and depalletizing system in a very confined space and implementing it in the brewery's halls.

The system consists of pallet transport as a roller conveyor with an integrated pallet control. Good pallets are transported by the robot via the gripper head to the palletizing station. Bad pallets are rejected linearly on the pallet conveyor.

The heart of the system, the Yaskawa robot, uses a gripper head to skilfully maneuver the empty as well as full beer crates and the Euro pallets through the safety area to the respective target position. The stacking station with the subsequent pack conveyor transports the empty crates to the sorting station, from where the false crates are easily conveyed out of the system again via an integrated roller conveyor. The new bottle conveyor between labeler and the packer transports the bottles cleanly into the existing packer. From the packer, the crates with the excellent brew are conveyed towards the decrating station, which assembles a complete layer (8 crates) to the clamping head for palletizing. The robot then goes about its work and stacks the crates with the noble drop onto the pallets. These are made available to the forklift driver and are now ready for their journey to the beer connoisseur.

The line is installed in a very small space of approx. 43m². The filling capacity of the line is 15,000 bottles/hour, which the palletizer and depalletizer can easily handle, including overflow.

A second expansion stage to a repacking line would still be possible here, which would make the line an absolute space miracle.